Your Cart is Empty

DESIGNED IN SEATTLE | MADE IN SEATTLE

DESIGNED IN SEATTLE | MADE IN SEATTLE

12 Unique Benefits of Carbon Fiber

January 15, 2020 6 min read

From sunglasses to wallets, there are dozens of different accessories we carry around every single day. These can be made from a variety of products, but carbon fiber is making a name for itself as a durable and eye-catching option.

What is Carbon Fiber?

Carbon fiber falls into a category of materials known as “fiber-reinforced plastics,” which also includes materials like fiberglass, used widely for boats and cars, and Kevlar, best known for creating bullet-proof vests. Combining the super-strong carbon fabric with advanced plastics enables the creation of a material with properties that seem almost impossible: it’s lighter than aluminum yet stronger than steel, doesn’t change size as it heats or cools, is incredibly stiff and rigid, and that’s just a start. Uses of carbon fiber are found in a wide range of industries, with new applications being discovered daily. It makes airplanes more efficient, cars faster, drones lighter, and is even found in many luxury goods such as wallets, sunglasses, and belts. CF’s own CF-LexTM hinge has even made it possible for carbon fiber to flexible as well as strong! Get ready to explore the many benefits and uses of the strange and unique material called carbon fiber.

12 Unique Benefits of Carbon Fiber Products

The only way to decide if carbon fiber is right for you is to learn how it works. Below you will find twelve benefits of carbon fiber that set it apart from other materials!

High Tensile Strength and Stiffness

The strength of carbon fiber comes from the reinforcing fibers: thousands of microscopic strands of bonded carbon which by themselves are strong in tension, but lack stiffness and resistance to compression. By suspending them inside epoxy resin (a strong and lightweight plastic) they become stiff along their axis and strong in both tension and compression. This creates “non-isotropic” strength, meaning the strength of the material varies depending on the direction and orientation of the fibers. This contrasts with an “isotropic” material like steel which has the same properties regardless of alignment. When properly aligned, a carbon fiber part can have a strength comparable to the best steel at a small fraction of the weight. This makes carbon fiber a great replacement for metals like aluminum and steel because it’s strength can be tailored exactly to its load scenario.

Lightweight

Speaking of weight, carbon fiber is light! A carbon fiber reinforced plastic isn’t much heavier than a non-reinforced plastic. When compared to steel, the overall weight reduction is about ninety percent. A 70 pound steel car hood can be re-created to weight a mere 7 pounds! It’s lighter than aluminum and even titanium. The soon-to-be-released Polestar One sports-car developed by Volvo, for example, saves over 500 pounds with strategic use of carbon fiber, while at the same time improving stiffness in key areas. CF’s carbon fiber sunglasses are so light they only weigh 20 grams; that’s equivalent to just six pennies!

Suitable for a Variety of Uses

In addition to its extensive use in the high-end automotive world, carbon fiber is being applied in almost every field you can imagine. Hikers love its lightweight properties in backpacks and tents and drones, planes, and helicopters can significantly improve their power-to-weight ratios. Don’t be surprised if carbon fiber pops up in a luxury RV, the emergency room, a musical instrument, or your next bicycle. In fact, CF has made products for each of those applications! Ever tried to lift a couch and wished it weighed a little less? You’re not the only one, and carbon-fiber furniture is starting to save over-stressed spines, one at a time. Despite carbon fiber being know for being a bit itchy, there is even a company making carbon fiber apparel t-shirts now!

Doesn’t Rust

Most materials react poorly to air and water, corroding, oxidizing, or simply breaking down unless protected. Not carbon fiber. Both the carbon and the epoxy resin are extremely stable and non-reactive, even when submerged in water! Ideal as a replacement for steel under conditions of extreme moisture or even submersion. There’s no need for expensive anti-corrosion treatments or continual re-painting.

Transparent to X-Rays

Despite being stronger than steel, carbon fiber is totally transparent to x-rays. The medical applications for this are boundless, as no other material combines the strength of metal with the x-ray transparency of plastic. Imagine if instead of having to wheel a patient to a whole new room for an x-ray, they could simply be imaged live through an operating table! Carbon fiber is unlocking this and other applications, creating new and exciting possibilities for doctors and surgeons.

Won’t Bend or Change Shape in Hot Weather

By using a high-temperature epoxy resin carbon fiber can be made to withstand extreme heat and cold with essentially no warping or change in size. This is due to carbon fiber’s property of low thermal expansion. Musicians have long dreamt of a guitar, harp, or violin that never go out of tune. Carbon fiber is bringing that dream to life, building musical instruments that don’t expand or contract when exposed to heat, cold, and humidity. Now instruments can survive exposure to the elements, rough handling, travel, and more, all while weighing less and offering decades of service. It can still be wise to coat carbon fiber with a clear-coat to protect it from its one weakness: UV exposure. With a proper coating, however, a carbon fiber part can survive years of sun-exposure.

Resistant to Chemicals

Carbon fiber (in its rigid form) is typically used in unison with a polymer matrix. Most commonly carbon fiber is paired with an epoxy resin system. Epoxy is formed from a two-part chemical reaction of a resin and a hardener. Once cured, epoxy is a thermoset that will not melt or return to its former constituents. This makes for a highly chemical resistant plastic that will not corrode, dissolve, or melt over time. This epoxy is what makes carbon fiber so chemically resistant to most alcohols, acids, and other chemical compounds.

Good Heat Conductor

At the atomic level, carbon fiber is composed of the same material that forms charcoal—carbon. Due to a property know as thermal conductivity, heat is readily conducted along the length of the fibers. Carbon fibers have a thermal conductivity of about 500 W/mK (watts per meter-kelvin), compared with about 200

W/mK for aluminum or 400 W/mK for copper. However, heat doesn’t conduct perpendicularly to the fibers which allows the flow of heat to be controlled through the part by arranging the direction of the fibers to create the desired thermal properties.

Flexibility and Malleability

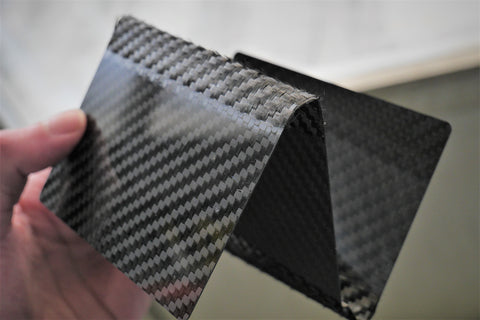

Prior to the lay-up process carbon fiber can be conformed to nearly any shape, although significant experience and technical know-how is required to adapt the process and material to various geometries. That’s not where it ends though. Composites can be made to be either flexible or stiff, but not both. That all changed in 2013 when the founders of Common Fibers developed a patented carbon fiber hinge CF-LexTM. A single continuous piece of carbon fiber can be made to bend along a single axis while still maintaining most of its tensile strength. Carbon fiber brackets can be bent like steel, fashion accessories can be made with that extra bit of flare, and countless new applications are waiting to be discovered. Common Fibers’ wallets were the first example of this carbon fiber hinge.

Visual Appearance and Aesthetics

If there’s one attribute nearly everyone knows about carbon fiber, it’s the instantly recognizable look. From the aggressive shark-tooth pattern, the depth, and the way it catches the light, carbon fiber can’t be missed! The fibers that provide that stunning appearance are more than decorative—they’re also the structure and strength of the part, like an insect’s exoskeleton. Whether it’s a super-car made almost entirely of carbon, a simple accent on a piece of furniture, or simply a wallet or knife you carry every day, carbon fiber is beautiful, striking, and bold. Carbon fiber can now even be woven into other patterns or with other materials to add some color (typically Kevlar, fiberglass, or Mylar). Carbon fiber by itself cannot be any color other than black.

Can Be Combined with Other Materials

The lay-up process involves sandwiching many layers of carbon fiber together and often a manufacturer will choose to insert a different material into the lay-up to create different properties. Race cars, for example, will often add an outermost layer of Kevlar, to protect the carbon if the part should encounter abrasion from pavement or a sidewall. Foam can be used to increase thickness with minimal increase in weight. Wood is vastly cheaper than carbon and adds flexibility and springiness. Even metal can be laminated to carbon, creating a truly remarkable composite material. The possibilities are nearly endless. That’s the magic of composite materials, and technicians and scientists are continually inventing new and innovative combinations of the material.

Conclusion

The benefits of carbon fiber are hard to count, but we’ve done our best to show you twelve unique reasons to choose carbon fiber. Even though it’s been around for half a century there’s still so much more to discover. You can read more from our DIY Blog to see carbon fiber in action and learn more about the nitty-gritty behind-the-scenes action that creates those remarkable parts, or check out our online store and experience carbon fiber for yourself. One thing’s for certain—once you go carbon there’s no going back.

If you have any other questions about carbon fiber, feel free to reach out! We are here to help!

Subscribe

Sign up to get the latest on sales, new releases and more …