Your Cart is Empty

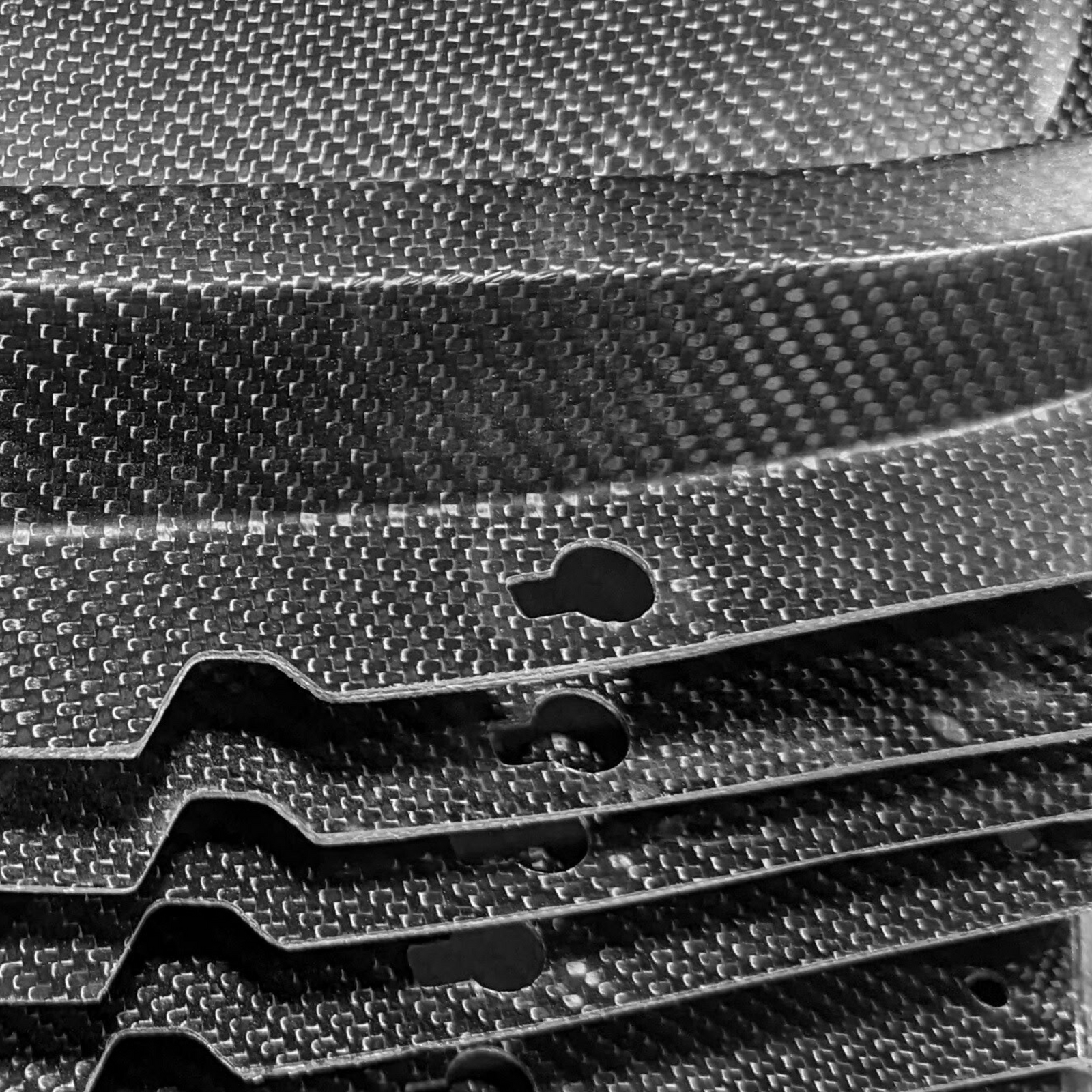

WHAT DOES A PRODUCT DEVELOPMENT PROJECT LOOK LIKE AT CF?

CF will assist you through the initial design to ensure all aspects of composite DFM are considered for quality, repeatability, and cost. We then work with you to produce prototype parts from low cost tooling to get you to market.

INDUSTRIES SERVED

Commitment To Development

DFM

Allow us to provide a comprehensive Design For Manufacturing analysis of your product to ensure that cost, repeatability, and design goals are met painlessly.

Prototyping

Through the use of 3D printing and prototype tooling, we can make parts that can be held and tested before investing in expensive production tooling.

Scaling to Production

With Common Fibers' in-house prototyping, tooling, and production departments, we can scale your project to any size at any pace.

Testing

Composites are historically difficult to predict through FEA and classic design tools. Through use of destructive and non-destructive testing methods, we can verify designs before they are brought to market.